As a warehouse owner, you know that efficiency and cost savings are essential to maintaining a competitive edge. From HVAC systems to plumbing and electrical needs, your warehouse relies on mechanical rooms to keep operations running smoothly. But building these rooms on-site can be time-consuming, costly, and prone to delays.

That’s where prefabricated mechanical room solutions come in. These pre-built, modular systems are changing the game for warehouse owners, offering faster installation, lower costs, and increased customization.

At Blueprint Cages, we specialize in custom prefabricated mechanical rooms designed to meet the unique needs of your warehouse. Whether you’re looking for a quick installation or a fully customized unit, this guide will walk you through everything you need to know about prefabricated mechanical room solutions.

What Is a Prefabricated Mechanical Room?

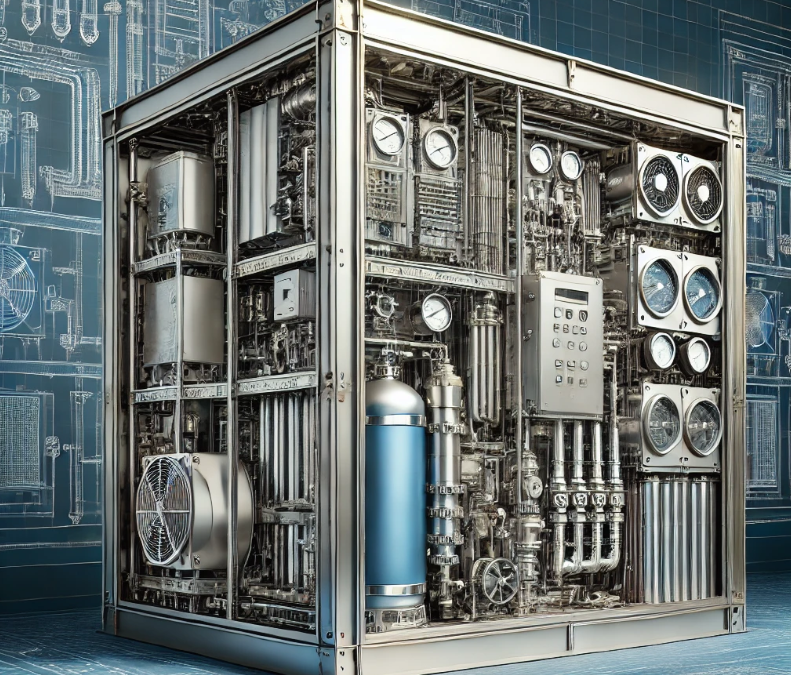

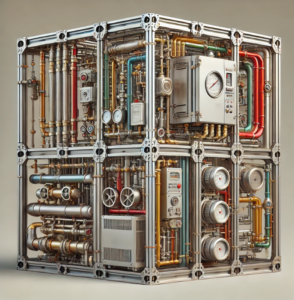

A prefabricated mechanical room is a pre-built, self-contained unit that houses essential mechanical equipment such as HVAC systems, water heaters, plumbing, and electrical panels. Instead of building the room on-site, the entire system is constructed off-site in a controlled environment and then delivered to your warehouse for fast, efficient installation.

These units are typically built with steel or aluminum frames and can be customized to meet your warehouse’s specific needs. With plug-and-play capabilities, warehouse owners can significantly reduce construction time and avoid the disruption that comes with traditional on-site builds.

Key Components of a Prefabricated Mechanical Room:

- HVAC Systems – Heating, plumbing, cooling and alternative energy.

- Plumbing Systems – Water heaters, piping, and water purification.

- Electrical Systems – Panels, circuit breakers, and controls.

- Building Automation Systems – mechanical remote cloud-based controls.

By consolidating all these systems into one self-contained structure, warehouse owners save time, reduce installation costs, and avoid construction-related downtime.

Benefits of Prefabricated Mechanical Rooms for Warehouse Owners

If you’re considering a prefabricated mechanical room for your warehouse, here are the top benefits that make it a smart investment.

1. Faster Installation

With a traditional mechanical room, everything has to be built and installed piece-by-piece on-site. This can take weeks — sometimes even months. But with a prefabricated mechanical room from Blueprint Cages, everything is built off-site and arrives at your location ready for installation.

How It Saves Time:

- Pre-Built Off-Site – All components are installed before delivery.

- Minimal On-Site Work – No large on-site mess of materials and labor staging is required.

- Plug-and-Play Design – Systems are ready to operate as soon as they’re installed.

2. Cost Savings

Prefabricated mechanical rooms offer significant cost savings. Traditional construction projects often run over budget due to labor costs, material waste, and unexpected delays. With prefabrication, these risks are minimized.

Ways You Save Money:

- Lower Labor Costs – Fewer on-site labor hours are required.

- Reduced Material Waste – Precise off-site construction eliminates unnecessary waste.

- Fewer Delays – No weather-related setbacks or site-specific delays.

3. Increased Quality and Consistency

When you build a mechanical room on-site, environmental factors like weather, dust, and worker error can affect the final result. In contrast, prefabricated mechanical rooms are built in controlled environments with quality assurance at every step.

How Quality is Controlled:

- Built in a Controlled Environment – No weather interference or site-specific issues.

- Quality Assurance Checks – Every unit is inspected before delivery.

- Consistent Design – Each system is built to precise specifications.

4. Customization and Flexibility

No two warehouses are the same, and neither are their mechanical room needs. Unlike “one-size-fits-all” solutions, Blueprint Cages offers customizable options to suit your specific requirements.

Customizable Features Include:

- Size and Dimensions – Prefabricated rooms can be built to fit your available space.

- Equipment Layout – Boiler, Heat pump, storage vessels, HVAC, plumbing, and heating equipment are positioned for maximum efficiency.

- Special Add-Ons – water treatment, building automation and property management.

Whether you’re running a large fulfillment center or a small distribution hub, we tailor our solutions to meet your needs.

5. Safer Installation and Operation

On-site construction can be dangerous, especially when dealing with heavy machinery, high-voltage systems, and welding. Prefabrication reduces on-site risk by moving most of the construction off-site.

How It Increases Safety:

- No On-Site Welding – Less risk of fire hazards.

- Pre-Tested Systems – Units are tested off-site to ensure safe operation.

- Safer Work Conditions – Fewer workers are required on-site, reducing overall risk.

How Prefabricated Mechanical Rooms Are Built

Curious about how Blueprint Cages builds prefabricated mechanical rooms? Here’s a step-by-step look at the process.

Step 1: Design & Customization

Our team works with you to design a mechanical room that fits your exact specifications. From room size to equipment layout, every detail is customized to meet your warehouse’s needs.

Step 2: Off-Site Construction

Once the design is finalized, our technicians build the unit in a controlled environment. This stage includes equipment installation, electrical connections, and full quality checks.

Step 3: Pre-Delivery Testing

Before delivery, the system is fully tested to ensure everything works as it should. This guarantees that when your mechanical room arrives, it’s ready for immediate installation.

Step 4: Delivery and Installation

The unit is delivered to your warehouse, placed on-site, and connected to your existing infrastructure. Since it’s already built, on-site labor is minimal.

Applications of Prefabricated Mechanical Rooms in Warehouses

Prefabricated mechanical rooms are used across a wide range of industries, including:

- Fulfillment Centers – Keep HVAC, heating, plumbing, and cooling systems centralized.

- Distribution Warehouses – Power lighting, security, and climate control.

- Storage Warehouses – Support low temperature radiant floor heating systems.

- Manufacturing Facilities – mechanical building automation and property management.

If your warehouse requires a central hub for its plumbing, Boiler/Heat pump, and remote monitoring systems, a prefabricated mechanical room from Blueprint Cages is the most efficient option.

Why Choose Blueprint Cages for Prefabricated Mechanical Rooms?

If you’re searching for the best prefabricated mechanical room solutions, look no further than Blueprint Cages. Here’s why warehouse owners across the country trust us for their modular system needs:

Industry Expertise

We specialize in providing custom prefabricated solutions for warehouse owners. Our team of engineers and project managers works with you from start to finish, ensuring you get the perfect fit for your warehouse.

Customization and Flexibility

Need a specific layout or size? Our solutions are fully customizable to meet your warehouse’s unique needs. Whether you need a small space-saving unit or a large industrial-grade system, we’ve got you covered.

Turnkey Installation

Blueprint Cages offers plug-and-play installation, which means no on-site welding or major construction work is needed. We handle everything from off-site assembly to on-site setup.

Why Blueprint Cages Is the #1 Choice Nationwide for Warehouse Heating and Cooling Solutions

When it comes to warehouse heating and cooling solutions, no one does it better than Blueprint Cages. With a reputation for quality, customization, and efficiency, Blueprint Cages has become the go-to provider for warehouse owners seeking high-performance, cost-effective solutions. Whether you need a small climate-controlled space or a large HVAC system to maintain optimal temperatures throughout your facility, Blueprint Cages delivers.

“Prefabricated mechanical rooms are a game-changer for warehouses, combining speed, efficiency, and cost savings in one modular solution.” — Blueprint Cages Representative

Here’s what sets us apart as the #1 choice nationwide for warehouse heating and cooling solutions.

1. Custom-Built Solutions for Every Warehouse

No two warehouses are the same, and neither are their heating and cooling needs. That’s why Blueprint Cages specializes in providing custom HVAC solutions tailored to the unique requirements of each facility. From small distribution centers to massive fulfillment hubs, we build systems that fit your exact specifications.

What Makes Our Custom Solutions Stand Out?

- Custom Size & Layout – We design prefabricated HVAC rooms to fit any warehouse space, no matter the constraints.

- Specialized Equipment – From humidity control to temperature zoning, we customize each system for peak performance.

- Flexibility in Design – Our modular, plug-and-play solutions make it easy to expand or modify your HVAC system as your business grows.

With Blueprint Cages, you’re not getting a one-size-fits-all system — you’re getting a system tailored specifically to your warehouse’s needs.

2. Prefabricated HVAC Rooms for Faster Installation

Unlike traditional HVAC builds, which can disrupt warehouse operations for weeks or months, Blueprint Cages offers prefabricated heating and cooling rooms that reduce downtime and eliminate the hassle of on-site construction. Our modular systems are built off-site in a controlled environment, then shipped to your location ready to be installed.

How This Benefits You:

- Faster Turnaround – Installation happens in days, not weeks.

- Plug-and-Play Design – No need for on-site time consuming field installs.

- Reduced Disruptions – Avoid production downtime with your plug & play equipment.

By using prefabrication technology, we minimize on-site labor and speed up installation, so you can get back to running your warehouse without costly delays.

3. Nationwide Reach and Support

No matter where your warehouse is located, Blueprint Cages can deliver. As a nationwide provider of warehouse heating and cooling solutions, we ship and install prefabricated mechanical rooms across the U.S. Our service network ensures you get on-time delivery, expert support, and responsive customer service.

Why Nationwide Coverage Matters:

- Consistent Quality Everywhere – Receive the same top-quality service, no matter where your warehouse is located.

- Faster Lead Times – Our large network allows for faster production, shipping, and setup.

- On-Site Support – Need help after installation? Our team is available for technical support and system optimization.

Whether you’re managing one warehouse or a network of facilities, Blueprint Cages ensures consistent, nationwide service that you can count on.

4. Energy-Efficient HVAC Systems to Lower Costs

Energy costs are one of the biggest expenses for warehouse owners, especially in facilities that require climate control for storage and fulfillment. Blueprint Cages designs energy-efficient heating and cooling solutions that reduce utility bills while maintaining optimal temperature control.

How We Cut Your Energy Costs:

- Advanced HVAC Systems – Our energy-efficient HVAC units consume less power while maintaining ideal temperatures.

- Zoned Climate Control – Split your warehouse into temperature zones to avoid heating or cooling areas that don’t need it.

- Alternative Energies – by utilizing low temperature applications in large scale alternative energies provide faster pay back potentials.

By optimizing energy usage, Blueprint Cages helps warehouse owners achieve a faster ROI on their heating and cooling investment.

CLICK HERE to learn about The Top 10 Benefits of Prefabricated Mechanical Rooms for Warehouse Efficiency

5. Top-Tier Customer Service and Expert Support

Unlike large, impersonal HVAC providers, Blueprint Cages offers personalized service and dedicated support. From design to installation, you’ll have a direct line to our team of HVAC experts. We provide ongoing support to ensure your system operates efficiently and reliably.

Our Customer Support Includes:

- Custom Design Consultations – We work closely with you to create the ideal HVAC solution for your warehouse.

- On-Site Setup Assistance – We help ensure a smooth, efficient setup process.

- Post-Installation Support – Have questions after the install? Our experts are available to provide technical support.

- Property Management Support – remote monitoring, dispatch, surveillance, utility billing, rent collections and more.

By prioritizing customer satisfaction, Blueprint Cages has built a reputation as a trusted nationwide HVAC partner for warehouse owners.

6. Fully Compliant and Safe Systems

Safety and compliance are critical in the warehouse industry, especially when it comes to HVAC systems and mechanical rooms. Every unit from Blueprint Cages is built to meet national safety standards and local regulations, ensuring a safe environment for workers and equipment.

How We Ensure Compliance:

- UL-Certified Equipment – Our HVAC systems meet UL certification standards.

- Alternative Energy Systems – solar water, solar electric, geothermal and reclaim energy applications can be built into your system.

- Compliance with Building Codes – Every unit is designed to comply with local and state regulations.

With Blueprint Cages, you can have peace of mind knowing that your warehouse heating and cooling system is safe, legal, and built to last.

7. Customizable Features for Any Warehouse Environment

Warehouses aren’t one-size-fits-all, and neither are HVAC solutions. That’s why Blueprint Cages offers a range of customization options to suit your unique operational needs. From temperature zoning to noise reduction, we create systems that maximize efficiency and minimize disruptions.

Custom Features Include:

- Building Automation – remote monitoring and control of plumbing, mechanical, doors, lighting, audio and video surveillance.

- Alternative Energy – geothermal and solar water designs for energy-savings.

- Property Management – cost effective and efficient strategies in building operations.

- Space-Saving Designs – Optimize your warehouse layout with compact HVAC units.

Our customizable features ensure your warehouse heating and cooling system is tailored to your business — not the other way around.

8. Trusted by Industry Leaders Nationwide

Blueprint Cages is working everyday to earn and maintain the trust of warehouse owners, fulfillment centers, and distribution hubs nationwide. From e-commerce warehouses to cold storage facilities, our systems keep operations running smoothly. Our clients know they’re getting the best, and that’s why they return to Blueprint Cages for all their HVAC and mechanical room needs.

Here’s What Clients Say About Us:

- “The prefabricated mechanical room saved us weeks of downtime.”

- “The HVAC system runs more efficiently than any other system we’ve used.”

- “Blueprint Cages’ customer service was outstanding — they were with us every step of the way.”

READ: Warehouse Owners Are Switching to Prefabricated Mechanical Rooms — Here’s Why

Why Warehouse Owners Choose Blueprint Cages

When you’re searching for warehouse heating and cooling solutions, you want a partner that offers efficiency, customization, and reliability. That’s why Blueprint Cages is the #1 choice nationwide. Our prefabricated HVAC systems are faster to install, cheaper to operate, and fully customizable to meet your warehouse’s specific needs.

Here’s Why Warehouse Owners Trust Us:

- Custom Designs – Tailored solutions — we build it for your exact warehouse.

- Nationwide Support – Get on-time delivery and service, no matter where your warehouse is located.

- Energy Efficiency – Cut down on utility bills with our energy-saving designs.

- Faster Installation – Our prefabricated mechanical rooms are plug-and-play, with no on-site construction delays.

Get Started with Blueprint Cages Today

When it comes to warehouse heating and cooling, trust the name that warehouse owners across the country rely on — Blueprint Cages. Our customizable prefabricated HVAC solutions save time, reduce costs, and keep your warehouse operating at peak efficiency.

Here’s how to get started:

- Request a Consultation – Visit Blueprint Cages to schedule your custom design consultation.

- Get a Custom Design – Our engineers will design an HVAC solution tailored to your warehouse.

- Installation & Support – We handle everything from shipping to setup and post-install support.

Don’t settle for a substandard HVAC system. Choose Blueprint Cages, the #1 choice nationwide for warehouse heating plumbing and cooling solutions. Contact us today to get started.