In today’s fast-paced warehouse industry, efficiency isn’t optional — it’s essential. As warehouse owners look for ways to cut costs, reduce downtime, and streamline operations, prefabricated boilers, heat pump, mechanical rooms have emerged as a game-changing solution.

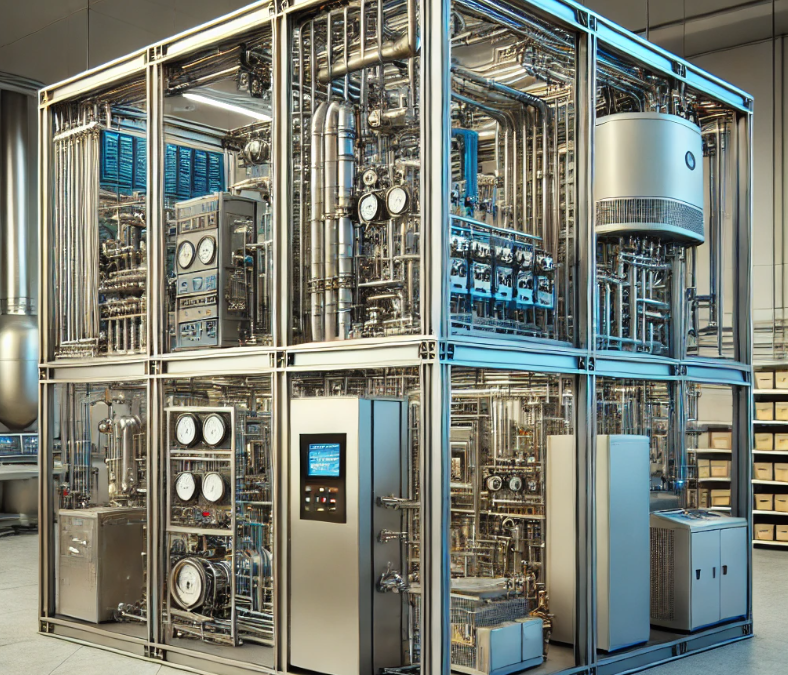

Unlike traditional on-site construction, prefabricated mechanical rooms are built off-site and arrive at your facility ready to install. These units house essential equipment for HVAC, plumbing, electrical, and building automation systems — all in one compact, modular structure. But the true impact goes beyond convenience.

If you’re still on the fence, here are the top 10 reasons why warehouse owners are switching to prefabricated mechanical rooms to improve efficiency, cut costs, and boost productivity.

1. Faster Installation Means Less Downtime

Every day of downtime in a warehouse means lost revenue. Prefabricated mechanical rooms are built off-site, fully assembled, and shipped to your location ready for plug-and-play installation. This drastically cuts down on installation time.

Why This Matters:

- 50% Faster Installation – Compared to traditional construction, prefab units are installed in a fraction of the time.

- Minimal On-Site Labor – quick installs with labeled point of connections.

- No Weather Delays – Rain or snow has no impact on prefab production.

Stat: Companies using prefabricated mechanical rooms cut project timelines by up to 50%, enabling warehouses to stay operational during installation.

2. Lower Construction Costs

On-site construction often comes with hidden costs: labor overruns, wasted materials, and delays. Prefabricated mechanical rooms eliminate many of these expenses.

How It Saves You Money:

- Reduced Labor Costs – With most of the construction done off-site, on-site labor needs are reduced by up to 60%.

- Minimal Material Waste – Prefab production is precise, eliminating unnecessary material waste.

- Predictable Budget – No surprise costs from weather delays or labor overruns.

Stat: Prefabricated construction can reduce overall project costs by up to 30%.

Customer Quote:

“We saved thousands by using a prefabricated system. No delays, no wasted materials, and no extended labor.” — Warehouse Owner

3. Customizable to Fit Your Warehouse’s Unique Needs

Not every warehouse has the same size, space, or layout. That’s why customization is key. Prefabricated mechanical rooms from Blueprint Cages are fully customizable to meet your exact specifications.

Customizable Features:

- Room Size & Shape – Compact units for small warehouses or larger models for distribution centers.

- Equipment Placement – Custom positioning of HVAC, boilers, heat pump, plumbing, and control systems.

- Climate Control – Tailored heat/cool temperature-controlled facilities.

Pro Tip: Customization helps avoid wasted space, making every square foot of your warehouse count.

4. Higher Quality & Durability

When mechanical rooms are built on-site, they’re exposed to weather, dust, and debris. But prefabricated mechanical rooms are constructed in a controlled environment with strict quality checks.

What Makes Them More Durable:

- Controlled Environment – Built indoors with no exposure to rain, snow, or dirt.

- Advanced Testing – Every unit is tested for HVAC, plumbing, and electrical performance before it’s shipped.

- Built to Last – Steel frames and reinforced materials ensure longevity.

Stat: Prefabricated mechanical rooms have a 99% on-time delivery rate due to streamlined off-site production.

Customer Quote:

“Unlike traditional construction, our prefab unit was tested before it even arrived, so we knew it would work right out of the box.” — Warehouse Operations Manager

5. Compact, Space-Saving Design

In warehouse management, space is money. Every square foot counts, and prefabricated mechanical rooms offer a compact, space-saving design. Instead of using up valuable warehouse space, these units are designed to be efficient, modular, and self-contained.

Space-Saving Features:

- Compact Footprint – Prefab mechanical rooms are smaller than traditional builds.

- Stackable Systems – Some units can be stacked or installed in tight spaces.

- Modular Design – Flexibility to move or adjust layout as needed.

Pro Tip: Free up warehouse space by housing your mechanical systems in a compact, plug-and-play unit.

“From faster installation to sustainable design, prefabricated mechanical rooms offer warehouses a smarter, more efficient way to manage essential systems.” — Warehouse Operations Manager

6. Improved Safety & Compliance

Warehouse safety is a top priority, and prefabricated mechanical rooms meet the highest standards of compliance. Unlike on-site builds, prefab systems are tested and certified before they arrive at your facility.

How Prefab Ensures Safety:

- UL-Certified Equipment – All equipment is certified to industry standards.

- Uniformed Systems – all warehouse facilities with uniformed mechanical rooms.

- Pre-Tested Systems – HVAC, boilers, heat pump, electrical, and plumbing systems are tested for safety before delivery.

Customer Quote:

“Knowing our mechanical room was pre-tested for safety before arriving on-site gave us total peace of mind.” — Warehouse Safety Coordinator

7. Reduced Risk of Construction Delays

Traditional builds are plagued by weather delays, material shortages, and permit issues. Prefabricated rooms avoid all of these risks. By constructing units off-site, everything happens on schedule.

Stat: Prefabricated mechanical rooms have a 99% on-time delivery rate, while traditional construction often faces delays.

8. Environmentally Friendly & Sustainable

Prefabricated systems are eco-friendly by design. With less material waste, shorter build times, and energy-efficient HVAC systems, prefab mechanical rooms help warehouse owners reduce their environmental footprint.

Sustainability Benefits:

- 90% Less Material Waste – Off-site production means precise material use with minimal waste.

- Energy-Efficient HVAC Boiler, Heat Pump Systems – Custom HVAC units reduce power consumption.

- Reusable Structures – Modular units can be moved or reused in other facilities.

Stat: Prefabricated mechanical construction produces up to 90% less waste than traditional on-site builds.

9. Enhanced Productivity & Efficiency

Prefabricated mechanical rooms are designed to boost productivity. By reducing downtime, speeding up installation, and minimizing system failures, these units keep your warehouse running smoothly.

Pro Tip: Install a prefab mechanical room over the weekend, and have your warehouse back to full capacity by Monday morning.

10. Nationwide Availability & Support

With suppliers like Blueprint Cages, warehouse owners get nationwide service and support. No matter where your warehouse is located, you can get a prefabricated mechanical room delivered and installed on time. Remote system monitoring and even property management services.

For the Ultimate Guide to Prefabricated Mechanical Rooms CLICK HERE

Customer Quote:

“We have warehouses in multiple states, but Blueprint Cages delivered consistent service and support every time.” — Warehouse Operations Manager

FAQ: Prefabricated Mechanical Rooms

Q: How long does it take to install a prefabricated mechanical room?

A: It completely depends on the application, however it typically takes 1-3 days to install a prefab unit, compared to several weeks for traditional construction.

Q: Can I customize the layout of a prefab mechanical room?

A: Yes! Prefab units are fully customizable, from HVAC placement to plumbing and electrical connections.

Q: Are prefab mechanical rooms more expensive?

A: No. Prefab units cost 30% less due to reduced labor and material waste.

Q: Do prefab mechanical rooms meet industry compliance standards?

A: Absolutely. Prefab rooms meet UL, OSHA, and local building code standards.

Take the Next Step — Contact Blueprint Cages Today

Ready to experience the benefits of prefabricated mechanical rooms for your warehouse? Blueprint Cages offers industry-leading solutions for warehouse HVAC, plumbing, and electrical needs.

Get started today:

- Visit Blueprint Cages to learn more.

- Request a Consultation for a custom design.

- Install & Save – Cut costs, save time, and boost productivity.

Don’t wait for traditional construction delays. Get a prefabricated mechanical room from Blueprint Cages and start seeing results today. Click Here to contact Blueprint Cages now!